Ritenga takirere whare o matarua kowiri tira hua e te makanga haumi i Haina te whakarewanga whakarewa kimahi miihini, maimoatanga wera, me nga ratonga maimoatanga mata.

RMC whakarewanga waahanga maitai maka tikaka tutuki, ka nui ake ranei i nga tumanako a nga kaihoko. Ka taea e te makanga haumi wax ngaro te whakaputahua whakarewa kowiri tirahe iti ki te tekau karamu me te nui ki te tekau kirokaramu, i roto i te whānuitanga o nga koranu ferrous me te kore-ferrous me te tino tika o te ahu.

Ko te tukanga whakangao haumi ware pi ngaro ka whakaputa i nga whakarewanga tata-kupenga-ahua e tika ana kia iti noa, kaore ranei he miihini taapiri. He pai ake te otinga atu i nga mea e taea ana ma etahi atu mahi whakarewa, hangahanga ranei. Ko te kaha me te mau tonu o nga waahanga whakarewa e pai ana mo nga tono whakakakahu-atete teitei e hiahia ana ki nga miriona huringa.

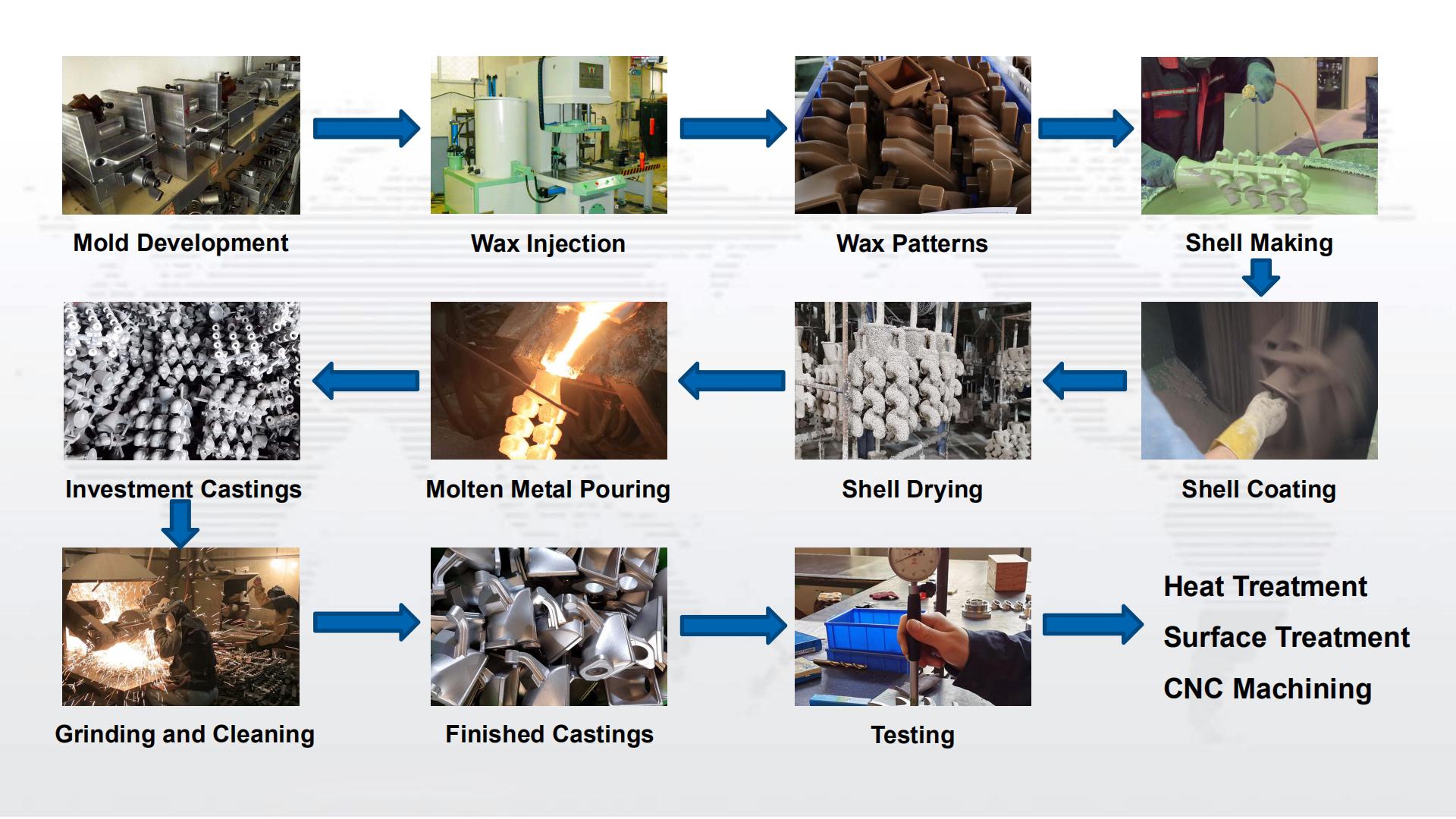

Nga Waahi o te Tukatuka Makanga Whakangao:

I te wa o te mahi makanga whakangao, ka whakakikoruatia he tauira ware pi ki te taonga uku, ka whakapakeketia, ka mau ki te ahuahanga o roto o te whakarewanga e hiahiatia ana. I te nuinga o nga wa, he maha nga waahanga ka maka tahi mo te tino pai ma te whakapiri i nga tauira ware pi takitahi ki te rakau wax pokapū e kiia nei ko te sprue. Ka rewa te wax i roto i te tauira - na reira i mohiotia ai ko te tukanga wax ngaro - ka ringihia te whakarewa whakarewa ki roto i te rua. Ka pakari te whakarewa, ka whakangaueuetia te maaka uku, ka waiho te ahua kupenga tata o te makanga e hiahiatia ana, ka whai i te whakaoti, te whakamatautau me te takai.

Duplex Stainless Steel (DSS) e pā ana ki te kowiri tira me te ferrite me te austenite mo ia kaute mo te 50%. Ko te tikanga, me 30% te iti rawa o nga waahanga. I roto i te take o te iti o te ihirangi C, ko te ihirangi Cr he 18% ki te 28%, me te ihirangi Ni ko te 3% ki te 10%. Ko etahi tira kowiri matarua kei roto ano nga huānga whakakotahi penei i te Mo, Cu, Nb, Ti, me N.

Kei te waatea te karaehe kowiri tira i te RMC Casting Foundry: 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770, A 890 1C, A 890 1A, A 890 3A, A 890 3A, A 890 3A, A 890 A 90 A A 995 4A, A 995 5A, 2205, 2507, 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N

Ko te DSS nga ahuatanga o te austenitic me te ferritic kowiri tira. Ina whakaritea ki te ferrite, he teitei ake te kirihou me te ductility, kahore he pakarutanga o te pāmahana rūma, me te tino pai ake te aukati i te waikura intergranular me te mahi fehokotaki, i te wa e mau tonu ana te pakaruhanga, te kaha o te waiariki, me te superplasticity rite ferrite kowiri tira. Ka whakatauritea ki te kowiri tira austenitic, he kaha te kaha o te DSS me te tino pai ake o te atete ki te waikura intergranular me te waikura hauota hauota. He pai rawa te kowiri tira Duplex he parenga waikura poka, he kowiri tira hoki te whakaora nika.

| Taurite Koeke o te Kowiri tira | |||||||

| NGA Rōpū | AISI | W-whakapapa | DIN | BS | SS | UNE / IHA | UNI |

| Martensitic me Ferritic kowiri tira | 420 C | 1,4034 | X43Cr16 | ||||

| 440 B/1 | 1,4112 | X90 Cr Mo V18 | |||||

| - | 1.2083 | X42 Cr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 S 17 | 2301 | F.3110 | X6Cr13 | |

| (410S) | 1.4001 | X7 Kr 14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 CrAl 13 | 405 S 17 | - | F.3111 | X6 CrAl 13 | |

| 416 | 1.4005 | X12 CrS 13 | 416 S 21 | 2380 | F.3411 | X12CrS13 | |

| 410 | 1.4006 | X 10 Kr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | X6 Kr 17 | 430 S 17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 Cr 13 | 420 S 37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | X30 Cr 13 | 420 S 45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 S 45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CrNi 17 2 | 431 S 29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | X10CrS17 | |

| 434 | 1.4113 | X6 CrMo 17 | 434 S 17 | 2325 | - | X8CrMo17 | |

| 430Ti | 1.4510 | X6 KrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 KrTi 12 | 409 S 17 | - | - | X6CrTi12 | |

| Kowiri tira Austenitic | 304 | 1.4301 | X5 CrNi 18 9 | 304 S 15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 S 19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S 21 | 2346 | F.3508 | X10CrNiS 18 09 | |

| 304L | 1.4306 | X2 CrNiS 18 9 | 304 S 12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S 62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S 16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316L | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316L | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S 33 | 2343 | - | X8CrNiMo 17 13 | |

| 317L | 1.4438 | X2 CrNiMo 18 16 | 317 S 12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S 12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S 17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S 24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Matarua Kowiri tira | S32750 | 1.4410 | X 2 CrNiMoN 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMoN 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

▶ Korehau me te Kore-kore mo teMakanga Whakangao, Te Tukanga Maka Wae Ngaro:

• Rino Kerei: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

• Te rino ngongo, te rino Nodular ranei: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

• Carbon Steel: AISI 1020 - AISI 1060, C30, C40, C45.

• Nga Paa Paariki: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo...etc i runga i te tono.

• Kowiri tira: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 me etahi atu kowiri tira.

• Parahi, Parahi Whero, Parahi, etahi atu konganuku koranu-a-Copper ranei: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

• Ētahi atu Rawa kia rite ki o hiahia motuhake, ki nga paerewa ASTM, SAE, AISI, ACI, DIN, EN, ISO me GB

▶ Nga kaha oHangahanga Makanga Taonga

• Rahi Nui: 1,000 mm × 800 mm × 500 mm

• Awhe Taumaha: 0.5 kg - 100 kg

• Te Mahinga Tau: 2,000 tons

• Rauemi Here mo te Hanga Anga: Silica Sol, Water Glass me o ratou ranunga.

| Ratonga | Whakaahuatanga |

| Nga Ratonga Maimoatanga Mata | Te Whakakikorua i te Paura, te Anodization, te Hikohiko, te Whakakikorua Chrome, te peita, te pupuhi o te kirikiri, te whakakikorua o te Nickel, te Zinc Plating, te pango, te whakakoi, te puru, te Geormet, te Zintek, etc. |

| Nga Ratonga Miihini Tika CNC | Miro, Miro, Hurihuri, Whakahonoretia, Mihi, Hoha, Miihini, Tapahi Waea Hiko, Miro...etc. |

| Te Tirotiro me te Mana Kounga | Spectrum Analyzer, CMM, Hardness Tester, Tensile Strength Tester, Yild Strentgh Testor, Te Hiri Hiri, Te Waahanga Whanariki Analyzer, Metallurgical Microscopy, Press Force Tester...etc. |